A laser engraving and cutting machine is a versatile tool that utilizes a high-powered laser to etch or cut various materials with precision. These machines are commonly used in a wide range of industries, including manufacturing, woodworking, signage, and more. They offer several advantages, such as high accuracy, speed, and the ability to work with various materials. Here’s an overview of the key features and applications of laser engraving and cutting machines:

Materials: Laser machines can work with a wide range of materials, including:

Wood

Acrylic

Glass

Leather

Fabric

Rubber

Plastics

Metals (with fiber lasers)

Engraving vs. Cutting:

Engraving: This process involves marking or etching a material’s surface with a laser, often used for adding designs, logos, text, or decorative patterns.

Cutting: Laser cutting involves slicing through materials to create intricate shapes and designs. This is particularly useful for creating custom parts, signs, and detailed artwork.

Applications:

Personalization: Laser engraving is commonly used for personalizing items such as trophies, gifts, jewelry, and phone cases.

Industrial Manufacturing: Laser cutting machines are employed in various industries for precise cutting and shaping of materials in mass production.

Signage: Laser cutting and engraving are used to create intricate and customized signs for businesses and events.

Art and Crafts: Artists and hobbyists use laser machines for intricate artwork, jewelry making, and other creative projects.

Software: Laser machines are typically controlled through dedicated software that allows you to create and edit designs, set cutting or engraving parameters, and send the job to the machine.

Safety: Laser machines can be hazardous, and operators need to take precautions to protect themselves from the laser beam and fumes generated during the process. Proper ventilation and safety equipment are essential.

Maintenance: Regular maintenance is necessary to keep the machine in optimal working condition. This includes cleaning the optics, checking alignment, and replacing consumable parts like laser tubes or lenses.

Laser engraving and cutting machines come in various sizes, power levels, and configurations to suit different needs. When choosing a machine, consider the types of materials you’ll work with, the level of precision required, and your budget. Additionally, it’s important to receive proper training and follow safety guidelines when operating these machines.

-

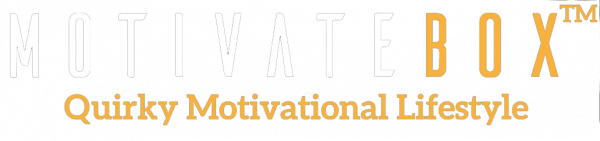

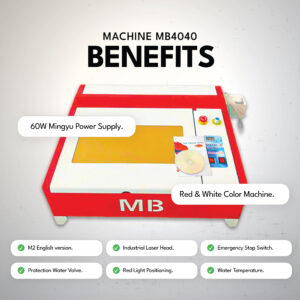

Laser Engraving Machine MB3020(50watt)

Rated 0 out of 5₹45,000.00A laser cutting and engraving machine is a versatile piece of equipment that uses a high-powered laser beam to cut and engrave various materials with precision. These machines are commonly used in manufacturing, prototyping, woodworking, signage, and the arts and crafts industry. -

-

-

-

Laser Engraving & Cutting Machine

Rated 0 out of 5₹375,000.00- A highly stable guide rail in this laser cutting machine gives high precision.

- The lens and mirror that we use in this laser cutter are high-quality glass and last long to serve you better.

A laser engraving and cutting machine is a versatile tool that utilizes a high-powered laser to etch or cut various materials with precision. These machines are commonly used in a wide range of industries, including manufacturing, woodworking, signage, and more. They offer several advantages, such as high accuracy, speed, and the ability to work with various materials. Here’s an overview of the key features and applications of laser engraving and cutting machines:

Materials: Laser machines can work with a wide range of materials, including:

Wood

Acrylic

Glass

Leather

Fabric

Rubber

Plastics

Metals (with fiber lasers)

Engraving vs. Cutting:

Engraving: This process involves marking or etching a material’s surface with a laser, often used for adding designs, logos, text, or decorative patterns.

Cutting: Laser cutting involves slicing through materials to create intricate shapes and designs. This is particularly useful for creating custom parts, signs, and detailed artwork.

Applications:

Personalization: Laser engraving is commonly used for personalizing items such as trophies, gifts, jewelry, and phone cases.

Industrial Manufacturing: Laser cutting machines are employed in various industries for precise cutting and shaping of materials in mass production.

Signage: Laser cutting and engraving are used to create intricate and customized signs for businesses and events.

Art and Crafts: Artists and hobbyists use laser machines for intricate artwork, jewelry making, and other creative projects.

Software: Laser machines are typically controlled through dedicated software that allows you to create and edit designs, set cutting or engraving parameters, and send the job to the machine.

Safety: Laser machines can be hazardous, and operators need to take precautions to protect themselves from the laser beam and fumes generated during the process. Proper ventilation and safety equipment are essential.

Maintenance: Regular maintenance is necessary to keep the machine in optimal working condition. This includes cleaning the optics, checking alignment, and replacing consumable parts like laser tubes or lenses.

Laser engraving and cutting machines come in various sizes, power levels, and configurations to suit different needs. When choosing a machine, consider the types of materials you’ll work with, the level of precision required, and your budget. Additionally, it’s important to receive proper training and follow safety guidelines when operating these machines.